Product Description

The most practical, safe and economical way to lift ferrous loads Realmagnetic's Lifter are a real revolution in magnetic handling of ferrous loads.

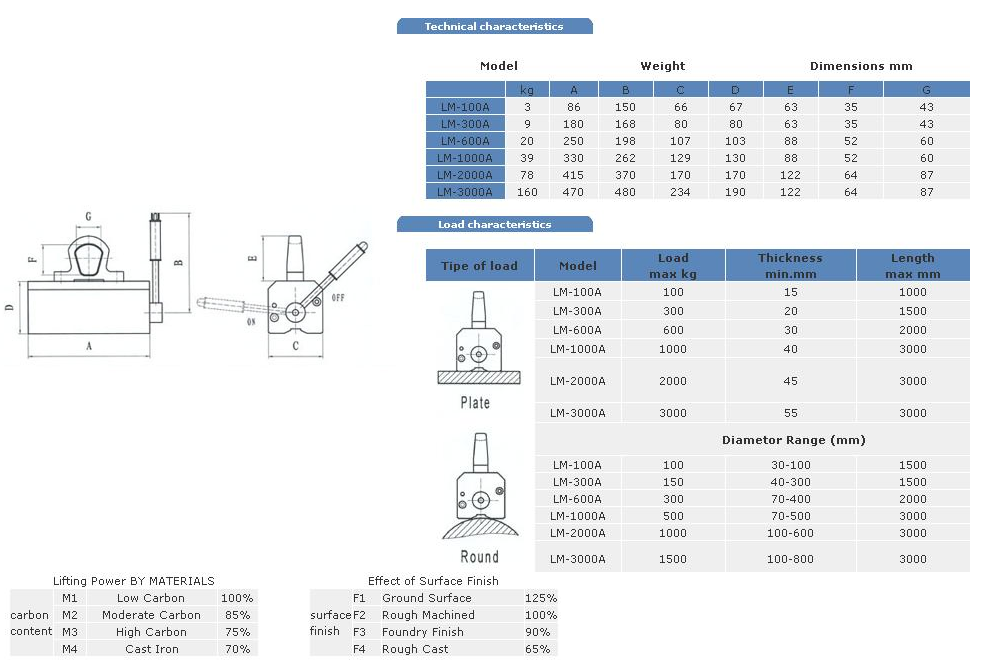

Absolute compact dimensions and low weight, great power and total work safety are the qualities, that make them the best answer with near zero operating costs and quick return on investment for all small and large shops in the industry. A range of 6 models with lifting capacity from 100 kg to 3000 kg , easy to use and manage,they give huge advantages in increased efficiency and productivity in a great number of uses even with little handling space and short range hoisting or lifting equipment.

Ideal for handling workpieces in machine tools and oxygen cutting operation, for plates, sheet and iron blocks in steel structural and naval works, in steel industries and distribution centers, for changing tooling in production and in general for all the requirements of the modern mechanical workshops.

A single operator can handle the load which is always anchored and lifted from the top without deformation or damage and with optimal use of the available work space, perfect human engineering and full safety for men and equipment. The load is held only by the power of the permanent magnets, lifting electromagnet with no power supply from the mains. The lifters of the ultimate generation. Unbeatable features and performance for a great engineering development.

Safe power:

High-energy permanent magnets, lifting electromagnets ensure great concentrated and steady power for an indefinite period.

The 3times safety factor of the recommended load to the test load ensures optimal working conditions even with substantial operating air gaps. The high magnetic strenght of the lifter is shown by the lever’s strong resistance to activation when load conditions are not perfect.

Concentrated power:

The channeling of the flow through the polar area only, i.e. only where it’s needed to ensure steady, optimal performance and total lack of magnetic dispersion while avoiding undesired attraction from adjacent loads.

HTMAG Permanent Magnetic Lifter is high performance ferromagnetic work piece lifter system with strong magnetic holding force made from high energy NdFeB permanent magnets. The handle movement changes the magnetic force of the lifter system to achieve hold and release the work piece. There is a steel ring on top of the magnetic lifter for hoisting, and a V-shaped groove at the bottom for holding objects with cylindrical surface. High concentrated and stable magnetic force was assured by super energy magnets, the load factor of safety is 3.5, even if there is big air gap between work piece and lifter, the lifter still can work very well.

Controlled manually by workers through its handle, Magnetic lifters can holding or release different shaped steel metallic working piece directly , like steel plate, steel pipe or disc steel, make it much easier for loading or unloading or moving work piece very, improve efficiency of hoisting works. So HTMAGNETS permanent magnetic lifter are widely used in factory, warehouse, etc.

FEATURE:

-

Use of high-energy magnetic material ensures a compact, lightweight and durable design

-

Maximum Breakaway force is 3:5 times

-

Simple locking switch handle enables safe, quick and easy one-handed operation with no "Kick Back"

-

Very low residual magnetism for quick and efficient handling of work pieces

-

Large shackle top fitting for easy attachment of slings and rigging

-

V slot in bottom lifting face for lifting rounds as well as flats

-

Clear markings of durations for varying

-

shaped work pieces, lifting conditions, air gap, steel thickness etc.

-

Individually fully proof load tested at manufacture

-

Compact and Sturdy:

Test load up to 100 times the weight of the lifter body (LM300). This incredible weight power ratio is provided by the double magnet circuit (rotor and stator) and the revolutionary construction.